|

|

Post by dickie on Jun 3, 2020 16:07:33 GMT

Hi Folks,

My airbox mould is now complete and has had seven coats of release wax now. I will make the first part from it at the weekend.

It has to be gelcoated then left for about three hours then a couple of layers of GRP. It stays in the mould for 24 hours to fully cure.

The car will be back home on Friday after work at which point I can have a look at spacing.

I have a remote filter on the way from Forge Motorsports which should be with me by the weekend.

|

|

|

|

Post by dickie on Jun 7, 2020 20:35:18 GMT

Hi Folks,

I have just taken the first part out of my airbox mould.

Ready to be trial fitted once I take to foam filter off I suspect I will have to re shape it to clear the brake balance valve.

The filter box from forge has arrived. It will be fun finding a home under the bonnet for it ! Its a bit fatter than expected,It might have to live in the OEM position.

The Manifold is heat wrapped already, with the addition of a heat blanket it should be fine with a bit of air ducted to it.

|

|

|

|

Post by dickie on Jun 14, 2020 20:17:36 GMT

The next stage of the airbox project has started.

As I am using the stock brake bias unit I have modified it to gain some clearance.

I took the foam filter off then covered the engine in a cloth before the butchery commenced,

I took the mounting bolt out and then cut the boss down by about 8mm, next job was to countersink the shortend boss.(I used a CSK bit in a 90 deg air grinder)

This gave me another 15mm of clearance, I had to rotate the fuel pipe fitting on the FPR to clear the front of the box.

I had to cut 10 mm from the flange face of the GRP mounting.

I now have the working basis of it. The internal depth is 75 mm with a trumpet length of 50 mm.

The next part of the operation is to cut a hole for the 52 mm intake pipe.

I will need to get hold of a bit of suitable pipe with a 45 deg bend to bond into the box.

|

|

|

|

Post by dickie on Feb 20, 2021 17:16:49 GMT

![https://www.flickr.com/photos/151310882@N07/50963059267/in/dateposted-public/]() Latest air box design, I have changed to the ITG filter as the forge motorsport one was too big !! ( The ITG filter is rated for 200 Bhp ) The filter will get some heat shielding once I have made proper mountings for it. The filler is holding the alloy pipe elbow into the prototype grp air box it is going to be smoothed off and once I am happy it all works I will take a proper mould from it and might make a carbon airbox from the mould, its a bit bespoke to my car but I have never seen an airbox for the PX500 backing plate, they all seem to be for the PX600. |

|

|

|

Post by Zed. on Feb 20, 2021 17:26:37 GMT

flickr is a pain to link  Rich. |

|

|

|

Post by dickie on Feb 20, 2021 17:34:25 GMT

|

|

|

|

Post by atlex on Feb 20, 2021 21:03:09 GMT

Looking good! gonna clean up the finish though ?  |

|

|

|

Post by atlex on Feb 20, 2021 21:04:25 GMT

BTW dickie if that's a regular working PCV valve it is doing nothing in your install, it'll restrict so much you won't see any flow past it, if you drilled it out or something, then it probably works lol. |

|

|

|

Post by dadbif on Feb 20, 2021 22:29:40 GMT

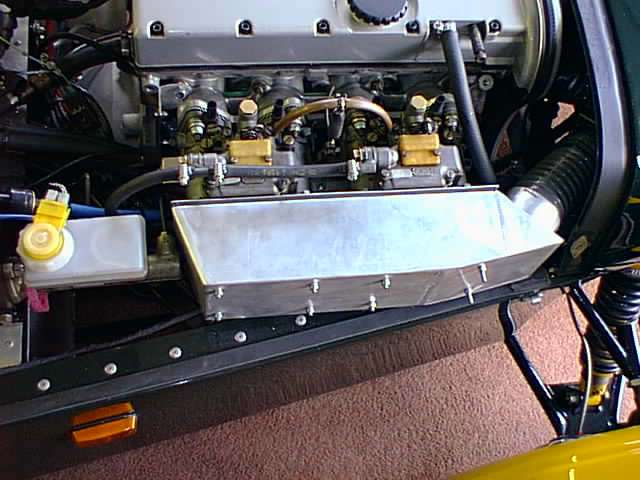

At last, been trying to upload this for a while. It’s the air box I made for my dellortos, similar to ITB’s. |

|

|

|

Post by dickie on Feb 21, 2021 12:27:47 GMT

Hi Atlex,

The PCV is gutted !!

I will make an alloy fitting to replace it.

The airbox is still work in progress, I will be smoothing it all off and will try and make a mould from it so that I can make a neater lighter one.

This is a modification of my first attempt with a better air inlet.

|

|

|

|

Post by dickie on Mar 16, 2021 18:33:39 GMT

Hi Folks,

Here is the latest version of my home made airbox mould pattern, It has to be a split mould to be able to take the airbox out. The raised plinth is to give enough room to laminate under the neck. There is still a lot of work to do before I can laminate the mould. This will be suitable for Pipercross pattern PX500 backplates.

I have a Danst ITB kit, the backplate and trumpets can be removed in one lump it only has to move about 12mm to clear after the four grub screws have been undone.

I had a few hours to waste at work until I had something proper to do.

So I had a play as we have a nice bandsaw at work and scrap melamine The Md was showing someone around while I was having a play !

He looked into where I was and made no comment. He probably thought I was making a part for an underwater vehicle.

|

|

|

|

Post by dickie on Apr 7, 2021 17:39:39 GMT

Here is the latest on the airbox mould, just removed from the pattern before trimming and cleaning up.

I hope the link above will work.

|

|

|

|

Post by dadbif on Apr 7, 2021 21:03:07 GMT

Looking very good! The shape looks the same as my old ITG filter backplate, are you going to use Dzus fasteners?

|

|

|

|

Post by dickie on Apr 12, 2021 18:38:16 GMT

![]() Hi Folks

If the links work this is the latest work on the Airbox,

The one in the picture is the pattern that I have taken the mould from,

The car will go to the tuners with it on this Thursday I am test fitting the brake bias valve on a spare master cylinder to check for clearance issues, As can be seen from the pictures the airbox is a little on the snug side, Its impossible to take the box off the backplate in situ. The Danst set up has the trumpets and back box held on with four grub screws. Once these are undone I can pull the complete assembly off the throttle bodies an rotate it and remove it forward off the car, as long as I unplug the IAT sensor from the backplate. The ITG air filter is rated for 200 BHP so I have a bit of headroom and the set up makes the car civilised to drive. The next pictures will be of the Carbon Fibre version in a few weeks time. I think that with this airbox I should be able to fit longer trumpets inside.

Cheers Dickie

|

|