|

|

Post by Bilbo on Dec 13, 2023 2:06:32 GMT

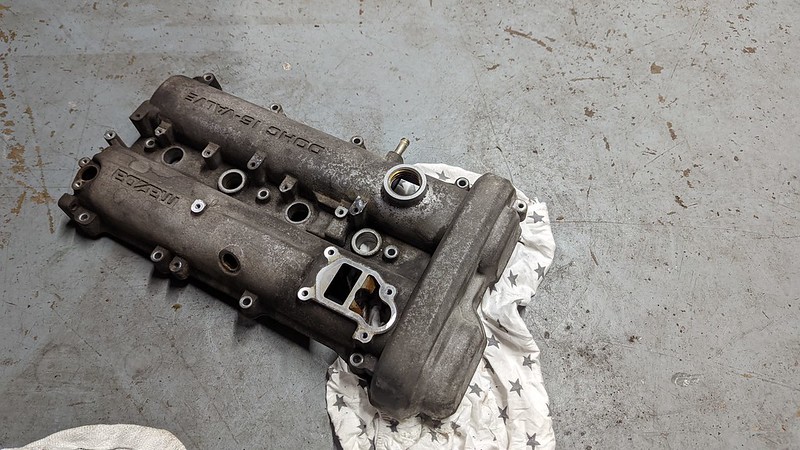

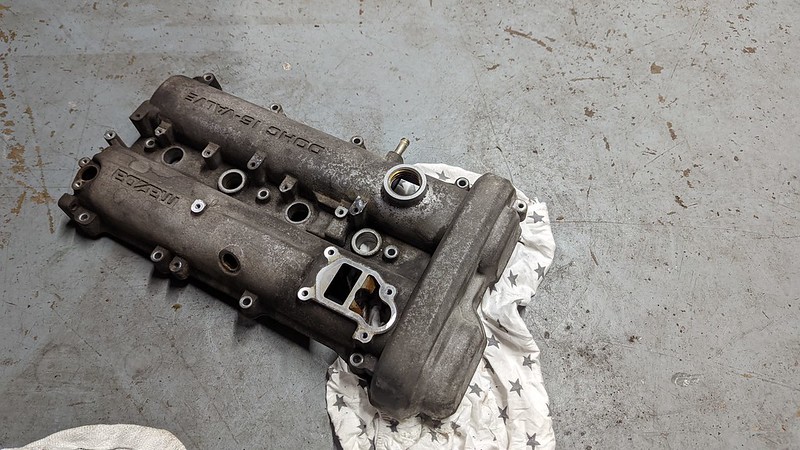

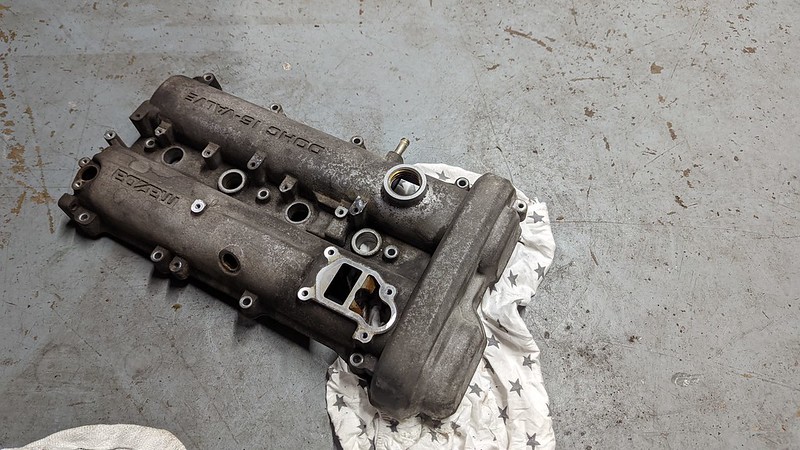

Ok so the driver's side leak. It was the door seal, here's what I did. Found the issue area, one very flattened door seal, still seems to be ok elsewhere despite being a bit flat with age, but the problem was here.  So I popped it off the door seam a bit, and found some not too rigid vac hose I had lying around. Made a small incision with a blade, and gently fed the pipe in, the length basically went to about half way into the bend that goes up the A pillar, so not much. But it wasn't leaking up there so didn't see the point, plus feeding it through the bend part was a total pain so I'm glad I didn't need to go much further.  I then sealed the hole up with some flexible waterproof sealant, and it was done. To be honest part of me is thinking this may have something to do with the not perfect door bottom, it's not gone, but it is corroded on the bottom worse than any of the other doors. When I paint the car I'll probably look at the lower seam of the door skin and maybe do some minor repair work on it. With that out the way I let the floor mat and carpet dry out and left it at that. Mate at the workshop recently got an absolutely smashed up MX-5 as a breaker, someone had a fight with a tree and lost 😂 I'll try and find a photo, it was properly mangled. Anyway he had various parts off of it for sale, but the engine was no good, front end hit had bent the bottom pulley, nasty. So I got the cam cover off of it nice and cheap, as wanted one to paint up.  Didn't want anything fancy, just a nice clean look, no bright colours needed for this. I did a fairly thorough job of cleaning it up, and then a half rear canoed job of masking everything, and a mate got annoyed with how imperfect it was, ripped it all off, and did one of the most precise beautiful masking jobs I've ever seen on a minor painting job before 😂 I went with a "black" metallic engine paint. I say "black" because it looks black, and says black on the can, but then it dries and it's more of a graphite than anything. Here it is still wet, but you get the idea:  Like I say nothing special, I may in-fill the letters on it at some point as well with a syringe or something, not decided on a colour for that yet, I think red would look tacky so may just go with white, or even cream to match the car when I paint it perhaps. We had previously had the OE steering wheel off, but the wheel I replaced it with (right when I first got the car moving) was bendy and too shallow (stalk hit wheel on full beam press). So I've run the OE wheel for the best part of a year. I had my resin wheel lying around that I took off the MX-5 when I broke it, and an MX-5 hub fits the Vauxhall column as I was informed some time ago, so I decided to give it a go in the Vauxhall. The OE wheel was proper on there, and I didn't want to bang and pull against the column, luckily another mate has just joined the unit who is a mechanic by trade, so he's got a load of heavy duty decent tools. Big old 2 prong puller and it was off within 2 minutes, with no damage to anything. New wheel on, to be honest I think a classic wooden OBA/Nardi etc. would suit the car better, but I had this already, and I just wanted to try out the car with a smaller steering wheel. Pretty pleased, overall not much heavier steering feel at all. I do have a couple of mates that have a couple of old school OBA wooden wheels, so I might try and buy one off them some time next year.  Note the phone mount on the right. It's an old one and I stuck it to the windscreen and it just kept falling off. Stared at it, then at the vent, and thought surely not. Pulled the original vent out and just applied a little contact adhesive to the back of the phone mount, and it literally squeezed into the vent hole like it was OEM, it is perfect. In all honesty don't like it there that much due to the increased chance of a grab and run thief through the window, but it'll do the job for now. Starting to plan respray for early next year, going to try and get some test/practice time in on the gun soon to get my eye in with compressor spraying (not done it before). My mate just drained the compressor which was long overdue, and I'm getting an in-line moisture trap for the gun on a painter mate's advice too. I still have a couple of litres of the paint colour I will be using for this car (same as my old MX-5), so will give it a go on a scrap panel and see how it comes out. I've already been planning where the car will sit in the unit for it. The back corner of our unit is perfect, isolate it with some decent thick greenhouse type sheeting, the fire door will be right behind it for fume extraction fans, the big unit heater is right above and behind it, so can kind of "bake" the car in the makeshift booth too. Should be ideal, I just need to get to grips with painting and give it a go, just like with everything else. Currently pencilled in for February time, gives me time to get the bits I need to prep the car etc. |

|

|

|

Post by Bilbo on Dec 21, 2023 16:24:51 GMT

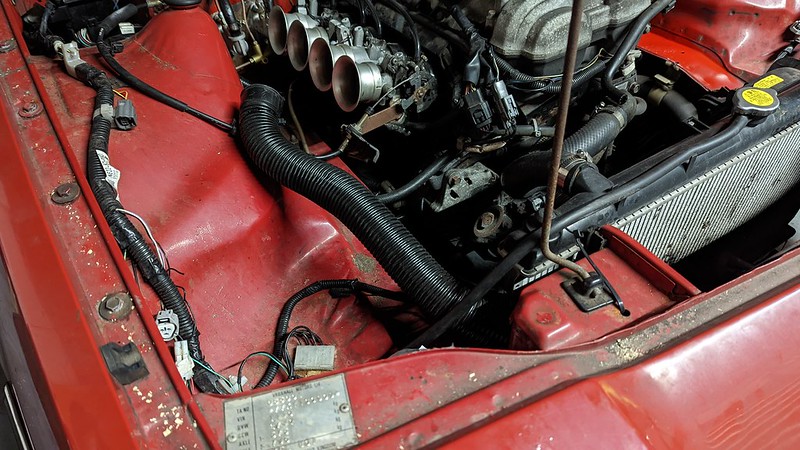

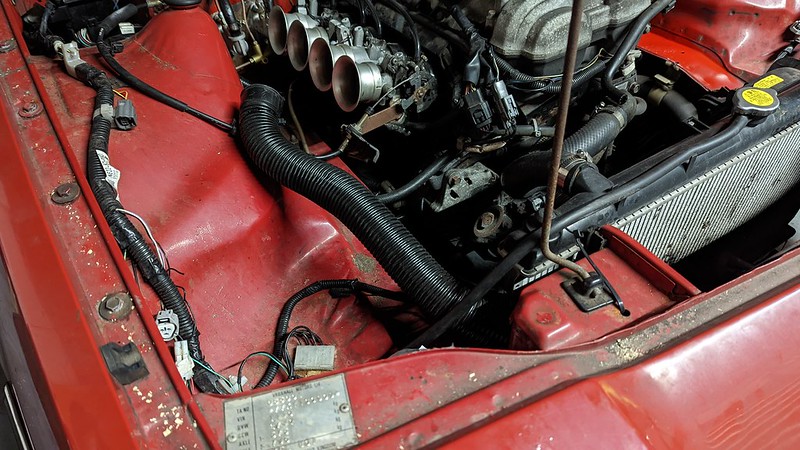

Keeping up with the small jobs at the moment. The top of the passenger chassis rail had pretty crappy paint on it even from the beginning. After doing the engine swap, all kinds of work in the bay it got worse and more chipped off as tools were left on it, fluids dropped on it etc. So I decided to clean it up and spray it as it was a mix of primer and bare slightly surface rusted metal. Got it all cleaned up and prepped. I used some decent anti-rust primer and the same red as I used at the back of the bay when I made my clutch master extension to the firewall. Looks a little off at first (it is Vauxhall Flame Red from Halfords, not the same red as the car), but when it dries/cures it looks almost bang on. Plenty good enough for an engine bay for sure. And it's just good to not have exposed metal anyway, so I'm glad to have it sorted.  I was routing about in my storage area looking for some bits and came across a few pieces of interior heater ducting I had to remove when I fitted the loom (wouldn't fit with all the wiring as well). A few bits of the original eyeball vent piping were just laying there, so I thought I might as well try making a basic rudimentary cold air feed. Inlet temps on the laptop aren't bad, particularly when moving, but it certainly can't hurt. So I routed the long pipe into the bay, and have used the oblong/oval end piece as an air inlet.   As with everything I do, this is v1.0. I don't like where I've put it, I am planning to move it into the small opening you can see just to the left of the number plate, I think that would work well. Wouldn't mind finding a slightly larger bellmouth for it, but it's definitely feeding some nice cold air to the trumpets when moving, so it's a start. Had a chat with my mate, he's just got a brand new galvanised chassis and bulkhead delivered for his old Defender, he's planning to full respray it when it's all rebuilt, also getting a 3.0 Tailgate McNoIndicate diesel engine so should be pretty decent when done. Anyway we've agreed to do all respray stuff around the same time, using the same makeshift booth plan I mentioned before. We're hoping to do it all in February, so I'll need to get a shift on getting the paint and consumables bought. I've got a brand new paint gun, and I'm getting a moisture trap for the airline, and then I'll need to try and source a red interior, or perhaps recover what I have (unlikely). Did consider lifting the black out somehow and just re-dyeing what I have but my mum does a ton of fabric/crafting/clothes making stuff and she wasn't too sure it wouldn't be effective/damage the fabric etc. so we will see. Either way the car will have a completely fresh new look by next spring which I'm so excited for! |

|

|

|

Post by Bilbo on Dec 30, 2023 3:19:17 GMT

Hope everyone had a good Christmas! I got a few car related presents which was nice, including a GPS speedo. I kind of want to make a new instrument cluster, change the look a bit and address the inaccurate fuel gauge etc. But for now I have just fitted the GPS speedo in front of the existing speedo.  Got it from my mum and dad for Christmas. There was an 80, 120, and 160mph option for these. 120 seemed the most sensible so went with that. Now this is only a cheap GPS speedo, and I really wanted an analogue style gauge rather than a digital readout, like the one I have been using on my phone. I've got to say for a cheap option it is incredibly accurate. Obviously there is a very minor delay when first setting off, but when driving along, it is bang on with my phone GPS, and I checked in 5th as I know 3,000rpm is exactly 70mph, and it is bang on accurate. Very pleased. It has a GPS aerial unit that I have place on the dash in the corner to pick up satellite signal, and I got it wired in, with the backlight wired into the car lights so it comes on and off with the lights as you would expect. 7 colours, I'm a fan of the red:  This location will do for now. It's nice getting in the car and not needing to load up the GPS app on my phone every single time. Decided I wanted to get a switch panel for various things, but not many options on somewhere to put it. So I removed the clock and original radio to utilise that space for something that will actually be used. Grabbed a piece of scrap steel I had lying around that was covered in surface rust and old test welds. Buzzed it back, and slowly cut it down to size. I wanted it to basically be an almost push fit into the remaining hole. Took a bit of back and forth but it here it is almost done:  It just about pushed into the plastic surrounding it, nothing holding it in at all and it stays put. Obviously when finalised I will use some screws/some form of adhesive to hold it in permanently. The idea is a bank of switches on the right side, and perhaps a small gauge on the left. I would quite like a proper oil pressure gauge, so that could be an option. For now I have just drilled out 6 holes for switches, painted it with some metallic caliper paint I had lying around, and fitted a couple of switches (only had 2 left so need to get some more). Made use of the new embossed sticker maker I got for Christmas, just to see how it would look. Only in prototype stage right now but it'll be a decent solution for what I need.  As for switches I will be using: FAN - I will be wiring in a second fan (using an MX-5 A/C fan in the stock A/C fan position on the rad), and just wiring this to directly operate from the switch. Had this setup on my old MX5 and it's a nice thing to have, just in case it's needed. AFR - Sometimes I'll have the ignition on and the engine off. Currently not ideal as the AFR gauge immediately comes on, and starts heating the o2 sensor, which isn't ideal in a cold condensation filled exhaust manifold. So having it manually switchable will be perfect. The big red switch will be for launch control. It already works, I have it set up on the ECU and it's hilarious, but I want to be able to switch it on and off as desired. Fuel will likely just be fuel pump control. The other 2 I've not decided yet, could do interior lights, or any number of other things, we'll see. |

|

|

|

Post by boggissimo on Jan 3, 2024 11:14:18 GMT

Love the big red switch, does it have a button underneath like on a fighter jet?  |

|

|

|

Post by Bilbo on Jan 8, 2024 15:39:36 GMT

Love the big red switch, does it have a button underneath like on a fighter jet?  Haha it does! Top Gun style. But not currently wired in. I'll wire them all in together when I've got some more switches. |

|

|

|

Post by Bilbo on Jan 16, 2024 23:54:51 GMT

So been getting a bit more drivetrain noise lately, I guess it was inevitable. Other than changing the rear axle oil I haven't touched it, or anything prop related beyond the front prop that I had made. Decided to start things off with the cheapest possible option, the centre bearing for the propshaft. Apart from one slightly stuck internal drive bolt for the torque tube, everything came undone super easily, and we replaced the torque tube bolts with brand new hardware when refitting, so that's taken care of. The centre support looks a little corroded, but otherwise in perfectly good condition. I haven't done the bushes on the car yet but the end bushes are in remarkably good condition for almost 44 years old.  We gave the Haynes a read and then a mate helped me get the centre donut rubber out, and remove the bearing from it. The donut rubber is also in amazing condition, I have read how difficult the OE ones can be to come by, and what I have read suggests any aftermarket ones can be a bit naff, so I was glad that it was still nice and flexible and not cracked or split anywhere at all.  We got the bearing out and it didn't seem to have any play, but when shaken a rattle noise could be heard, and the grease resembled something more like earwax 😂🤢  One side of the outer bearing casing was a real pain to get off, but with a bit of blowtorch action it popped off fine. Bought a 6205 2RS bearing, found that info looking through some old threads on the Manta forum, so that was handy. Popped it in the casing and smeared a little grease on the front edge as per the book's recommendation  Got it back into the donut rubber, and reinstalled into the centre support, bent the tabs back to retain it, and it was done. Refitted it all, not a bad job all in all. Took a little while but peace of mind that that bit is sorted now. Still have the drivetrain noise, I haven't done the rear wheel bearings yet, but I have found some in the Netherlands, so I will get those ordered soon and do the rear wheel bearings. There's a few noises, the MX-5 gearbox is a little whiney at speed, but there is a definite rumble from the rear, but also a slight whine. It could be my front prop, I have now measured and ordered a brand new UJ for the front prop and will sort that hopefully this weekend or next, as it has slight radial play in the joint (we repaired it previously with another used front prop coupling from an MX-5, so this is likely the reason it isn't liking being in the Vauxhall again). Hoping that a brand new UJ will solve the issue. Of course the issue could be the pinion bearing in the diff, and to be honest it may be the most likely cause of the whine, but that is the most expensive option, and it can't hurt to sort all this other stuff out too. Worst case I may just buy another axle, and maybe rebuild my existing one over a few months with no time constraints to have as a back up. |

|

|

|

Post by Bilbo on Feb 4, 2024 2:54:24 GMT

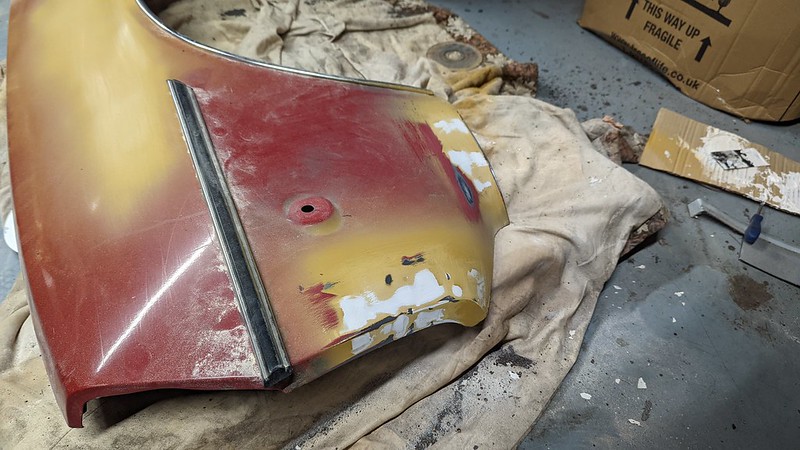

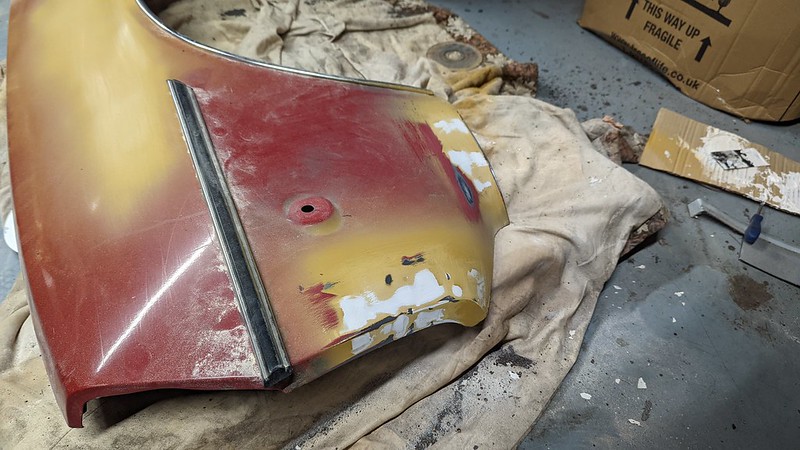

Right, lots going on! lets just start off with this:  Hell yeah. Anyway, there has been misery followed by success lately (with lingering misery too). First off, the rear rumble. Previously I said rear wheel bearings. However turns out that wasn't right, the rear wheel bearings are fine. The prop however, not so much. As I posted a while ago we fitted another MX-5 front yoke with original UJ. However the rubber seals were very worn. Needing to drive the car we just did what we could and called it a day. It drove fine for months but finally those failed seals led to grease escaping, which inevitably led to bearing cup needle wear, and eventually a few mm of play in the UJ side to side. At this point, as you can probably imagine, the rumble turned into a vibration. So I measured the UJ size and bought a new one, start fresh brand new UJ. It was a greaseable one, so I was concerned with it being hollow that it may be weaker, but we never got that far really. It didn't go well and that UJ was cut back out, and binned. I then bought a nice high quality GMB UJ.  Got the yoke cleaned up  Fitted  Originally staked, so once again tacked the caps in. All set, put it in. Horrendous vibration. Got car back on ramp, mate put it in gear and spun it up, prop front yoke very obviously not true. My mistake. Re-did it and got it nice and centred. Got it back in again. Vibration better but still not good at all. Babied it around at no more than 30mph and decided this was all just making me hate the car. So binned off that UJ, it was the right size but just couldn't get it quite right, and I could do without the cost of going back to JW for them to sort it all right now. So I got another MX-5 prop off a mate for free. I wanted the slip yoke with the original UJ, as we had done the first time, but this time being extra careful with the seals and cups. So instead of cutting the stakes off with a Dremel I decided to very very carefully cut the UJ out of the donor prop with the grinder, and then carefully chisel the last bit of metal off to free one cup completely, and then remove the entire thing with zero damage.  Great success  One perfectly intact original UJ. Slip yoke had some surface rust but a bit of fine sand paper and it was perfectly fine, no pitting or anything, all good. So with this out I carefully removed the 2 cups, took out as much old grease as possible, put in new bearing grease, and assembled the slip yoke onto my prop. All went perfectly well. Gearbox oil going back in, work smarter not harder. The motor struggles a bit with the thickness, but totally hands free and no gravity feeding or squeezing bottles until your hands hurt, just sit and have a smoke and let it do its thing:  Now this time I decided on a different method for retaining the cups into the prop. I don't have a staking tool, and I don't really particularly like tack welding the caps into the yoke directly, it's not a fun thing to do and puts quite a bit of heat into the cups which is probably not ideal. So this time I took 2 identical washers that were the exact size of the cup width (22mm), this also allowed me to visually centre the UJ perfectly, as these fat washers sat perfectly flush both sides when the UJ was centred. They butt right up against the caps, and then I tacked them to the yoke on the outside, retaining the cups in their position without needing to weld to them directly, much better solution, and much more easily serviceable if god forbid this ever needs doing again.  It's much neater, and just looks a lot nicer this way too. So all done, I took the car out and it's perfect. Zero driveline vibration whatsoever, it's just like the day I got it on the road. Very pleased. Sadly the damaged UJ had not gone quietly and had decided to leave some unpleasantness behind. The box whines a fair bit now in all gears, so I think the output shaft has been damaged in some way, but it still drives fine. Not the end of the world as I have 2 spares lying around. Unfortunately it has also damaged what I can only assume is the pinion bearing in the rear axle too. It's loud but again no vibration or other unpleasantness. I'll drop the oil soon to check it and refresh, and eventually I'll just get another complete axle and swap it out (rebuild kits cost more than another axle!) Anyway like I say, it drives mint now, so naturally it would be rude not to test it out properly. Spot on. Anyway, enough about props and UJs, I don't want to see, read, or hear anything about either word for a while now. Onto body prep. Respray is coming very very soon, my mate's Defender restoration and M57 swap is nearing completion and we are both looking to do full respray at the same time, with a makeshift booth in our unit. So started getting stuff ordered, pencilled in the respray for 2 weeks today. Anyway before I can prep I need to address the long ignored front wings firstly. The main bit of bodywork rust that needs to be sorted before respray. So off came the wings:  The not so bad one:  And the worse driver's side wing:  To be fair neither of them are really that bad in all honesty, perfectly saveable, just need to wire wheel back that awful crappy ancient underseal and properly protect them once they're welded.  Started on the worst wing. Got it cut back, had to cut back further than you would expect from the above, as the metal was getting very tired all around the hole. Got a plate cut, welded it in, and then started on one of my least favourite jobs, skimming filler.  Naturally I went way too thick in some areas, and caused a lot of extra sanding to get it flushed back to where it needed to be, Oh well, I'm a little out of practise, not done this for nearly 3 years now. Anyway once it was all sanded back nice enough, I went applied a decent few coats of filler primer. Most of this is hidden by the bumper, but might as well try and do it properly. Got the filler primer on nice and thick, and I will sand the high spots down, there were a few low spots so it should all even out. To be honest I'm pretty happy with this:  Re-fitted as is for now as I needed to drive the car home, but it's looking a lot better now than the big hole it had before:   The hole on the passenger wing is tiny in comparison so should be easy enough to sort without much fuss. Pretty happy the prep is under way, I'll be booking 2 days off work plus a weekend to do the sanding, removal of everything, masking, primer, and top coat. All being well 2 weeks from today the car will be freshly resprayed. Recap on the planned colour, the Photoshop I did a while back (ignore the poorly edited on A3As, I don't have a set of those sadly!)  Toyota Ivory, the same as my old MX-5 and my mate's AE86.  Looking at it now I do miss the 5, was a really lovely looking car when it was done, but the Vauxhall is the future, and much more interesting, so no time to be sad about it now haha. This with a full red interior eventually should look absolutely class I reckon. |

|

|

|

Post by Zed. on Feb 5, 2024 22:22:54 GMT

Recap on the planned colour, the Photoshop I did a while back (ignore the poorly edited on A3As, I don't have a set of those sadly!)  Toyota BEIGE, the same as my old MX-5 and my mate's AE86.  ps. photoshopped wheels DO NOT SUIT a 1970's Vauxhall, reminds me of the rEnAuLt 5 GoRdInI (actually a fast car but with suspect handling and they're french  ) Rich. |

|

|

|

Post by Bilbo on Feb 7, 2024 22:19:57 GMT

Recap on the planned colour, the Photoshop I did a while back (ignore the poorly edited on A3As, I don't have a set of those sadly!)  Toyota BEIGE, the same as my old MX-5 and my mate's AE86.  ps. photoshopped wheels DO NOT SUIT a 1970's Vauxhall, reminds me of the rEnAuLt 5 GoRdInI (actually a fast car but with suspect handling and they're french  ) Rich. Hmm you're right, those wheels would suit it much better if they were cream too. |

|

|

|

Post by Bilbo on Feb 11, 2024 3:17:21 GMT

Right so, primer and paint has been delivered, mixing cups, strainers, masking tape etc. etc. all arrived too, paint is on track for next week. So I needed to crack on with the worst parts of the bodywork to get it ready for full car sanding next week. First up was the boot the other night.  As you can see from this photo from a while ago, the left side of the bootlid had some proper poor repair respray at some point. Dodgy paint, matte in finish, and a hard mask line that was super obvious. The paint had crazed in this area, leading to some corrosion under and around the Cavalier badge. So I pulled the bootlid off, and the badges off, sanded it back, and luckily the corrosion was just cosmetic, cleaned it all away and then gave it a coat of filler primer ready to give it a sand to flat it off.  Sadly the primer reacted around where the badge would go, so I'll redo that in the next couple of days.  With that sorted enough for now I re-fitted to so I could drive home. Another long day today, this time sorting out the passenger wing. As shown before this wing is not as rusty as the driver's wing was:  But right on the curved part it was all so thin and rusting through, which made it a little more complex to fix properly:  Used a leftover curved piece of MX-5 sill/arch repair panel and cut it down to shape once I had cut out the affected area.  Little bit more finishing was needed after this, but it came out ok.  Little skim of filler after some grinding back:  Part way through:  And sorted:  I'm pretty happy with this! I still need to reattach the front trim clip holder somehow, but that is minor details, this is a lot better now. Now for the other bit, the really strange big long scratch in the main wing body. No idea what caused this, but it was like it when I got the car.  I don't know why, but I thought I could sort it by keying it up and trying some filler primer.  It just made it more obvious 😂 So I conceded defeat and decided to give it a really light skim all the way along the scratch, as well as one other area above the scratch too:   And sorted:   Little bit of finishing needed, but the scratch is completely gone now and it's looking a lot better. Glad to have these things out the way now. Not a lot of difficult bits like this left to do, so just trying to get them all out the way ready for next week. Not long now. |

|

|

|

Post by boggissimo on Feb 12, 2024 9:57:00 GMT

|

|

|

|

Post by Bilbo on Feb 13, 2024 2:46:16 GMT

Cheers mate, getting there! |

|

|

|

Post by Bilbo on Feb 13, 2024 2:46:29 GMT

Ok, so more work done tonight. First off the badges were getting a bit tired, the paint on the outside of the letter was all chipping/chipped off, and they just looked a bit crap. So I gave them a clean up, I was pleasantly surprised that they were metal badges and not plastic, quite cool I thought. So etch primer first, then some acrylic gloss black:  Let that set for a day and then pushed them into a foam mat on the locating pins to hold them still, and gave the faces a sand off with a flat sanding block:  Not bad! I went a bit hard on the sanding I think, particularly on the right side of the final 0, but oh well they look better than they did! Next up, the vents. The vents have been a pain since I got the car, the ones on the scuttle area. In standard form useful, but for me with extra wiring and holes drilled for loom around the firewall, initially water ingress into the car was an issue (have since sealed the loom points up better, but still). I didn't like how rain water could just rush in, work it's way onto and into the chassis rails, and then make it's way back out. Seemed pointless and a potential rust causer. So they had been taped up for over a year. Got all the tape residue off with some solvent, and decided on a plan.  I'm not touching that windscreen, it doesn't leak and it's not cracked. I'm not going near that windscreen seal either, it's perfectly good how it is, and I'm sure much like new front wings for one of these a new one would be basically unobtanium. So welding is off the table, no chance. Way too close to the rubber for my liking. Now I'm not a fan of this sort of work, I often see it done by bodge artists who patch over rust holes that should really be welded, but I honestly had no better solution, and I think it's gone well, seems strong too. Fibreglass filler. Normal filler at any kind of depth I feel will just sink over time, or crack. So I went with P40 instead of P38. Weird stuff! Not the easiest to spread evenly, and it smells worse than normal filler 😂 Anyway, gave it a go. Reverse side mesh in:  Filler applied:  Gross stuff, it even looks nasty when laid down, but god does it set hard! Sanded down:  Wasn't quite perfect, so gave it a very tiny skim of normal filler over it to get it nice and flush. Filler primer (yes the car is even more yellow now!):  Both done:  Honestly not my favourite thing I've ever done, but given the windscreen seal situation I really couldn't think of a more suitable method to get this result. It certainly beats getting a ton of water all over my loom whenever it rains. It has set super well, it feels insanely well bonded into those small thin vents, and the mesh underneath is also bonded to it super tightly, so I'm quite happy. Bit of sanding and finishing on the filler primer needed, but need it to harden first. Once that's done then this is sorted and I can crack on elsewhere. I have also bought some trim masking tape, with the little plastic edge, specifically for the windscreen rubber, so I can spray the paint on without getting a nasty hard edge against the rubber, looks like pretty good stuff! Excited now, but later this week is going to be a slog. Thursday: Wash the car thoroughly as it's filthy, remove everything (lights, bumpers, side trims etc.), DA all the main panels down, sand everywhere else by hand, mask the car up, build the makeshift paint booth. Friday: Final prep, spray primer Saturday: guide coat and wet sand primer down Sunday: Final checks and top coat I'll put the car back together some time next week when the paint has hardened in the unit with the heater on. |

|

|

|

Post by dadbif on Feb 13, 2024 8:33:29 GMT

You can protect your windscreen rubber when painting by easing a bit of electrical cable all around the seal, just enough to lift the edge off the bodywork, then when you spray there is no hard edge and the seal goes back over the paint when you’ve finished.

|

|

|

|

Post by Bilbo on Feb 19, 2024 2:58:51 GMT

Ok so an absolutely brutal 4 days, but we are there! Took 2 days off work at the end of last week to have a 4 day weekend to get the car painted. Thursday was fairly straightforward, some final sanding and starting to disassemble the car.  Friday turned out absolutely brutal, got there about 10:30am and left at 6am the next morning. Was a ridiculously busy day. Started out disassembling more bits. Lights off, door handles and locks off (those rear door handles are a pain to get to the nuts haha), chrome trims all removed, side bump strips, bumpers etc. etc.   Bit more work just smoothing out some areas, rubbing back surface rust patches on the lower doors, rear quarters/boot pocket areas etc. and adding a little filler primer where needed to get a smooth panel:  Found one rust hole, in the boot shut, very minor, and will sort that soon, but no time this weekend. It had sealer over it that had been done at some point in its life so I had never seen it before, and it was only when I agitated it with sanding that it showed itself.  Then it was masking time. The trim lift tape worked fine, super fiddly though and I hated every second of it 😂 Obviously I'm painting the door shuts, so the door openings all had to be masked fully to protect the interior, that wasn't much fun either.  Ran out of masking paper right on the final door, so my mate put this masterpiece of supermarket plastic bags together:  Every single trim clip bar 2 came off with zero damage and can be reused, which is great, very happy with that. Everything small bagged, and all trims and chrome labelled for easy re-fitting:  There's a lot more than that, but you get the idea. So with all that done it was time for final checks, helping be the paint mixer as my mate primed his Defender, and then panel wiping mine down and getting it primed. Slightly shaky start as I was nervous, but the primer went on well enough. No runs/reactions or anything like that apart from one small sag above a door handle, so pretty happy overall.   We used a high build primer which hid any imperfections or missed sanding scratches perfectly, and nothing seemed wrong at all. Sprayed some guide coat on for the wet sanding stage, to help identify areas left to do. The can decided part way through spraying that it would briefly turn into a normal black rattle can and just did this:  Very annoying 😂 no harm done though. Got in bed at 7am, had to get up at 8:30 to take my girlfriend to work. And then went straight back to the unit to wet sand the primer down. So obviously Saturday was a terrible day and I felt and looked like absolute death. But the wet sanding went well. My mate who painted my MX-5 popped in and gave some advice. Wet sanding was taking a long time as the primer surface was pretty rough, so he suggested just doing the bulk flat panels with a DA on low speed with 800 grit dry. So I did. It was perfect, easy to control, no burn through, and it was getting done super fast. Called it a day early and slept for a long time. Then Sunday we got cracking again, I finished the flatting back by going over everything, door shuts, bonnet and boot shuts etc. and any rough patches missed the day before. Got it all nice and smooth in pretty good time, fixed a bit of masking here and there that needed it, and then it was time. Colour going on. Had a couple of gun issues, but quickly rectified, and then it was time. Very nervous, the top coat was way thinner when made up than the primer. I was concerned about paint runs, but got cracking. 2 decent coats later and here we are:    Now it's not perfect. It's good, for a first time painting I'm pretty happy with this attempt, it has adhered well, it's evenly covered, and no reactions or other issues have occurred. One very small run on the entire car, which is in the rear passenger door shut, so I really do not care, it can stay there and probably never be seen. All of the vertical panels, doors etc. have all come out acceptably smooth, I'm very pleased. The panels that are horizontal, for whatever reason have a fair bit of orange peel. Glossy, but it's very noticeable. Maybe my technique, or something gun related, I really don't know to be honest. It can be fixed in a week or 2 with a wet sand and polisher, but I was a little disappointed. But honestly it is what it is, that can be fixed and then it'll look brilliant. All in all, horrible 4 days of graft and my back is killing me now, but we got there, both the Cavalier and the Defender are all painted, and the hard bit is out the way. The cheapy Amazon gun did an amazing job, impressed with it to be honest. The inline moisture trap also worked perfectly, not a single sign of moisture in any of the paint sprayed, very happy! |

|

)

)

le sigh

le sigh